GMPTEC Sight Gauges can be used in different positions and sizes within a GMP manufacturing process. Sight Gauges are necessary at certain points in production to be able to check visibly what is happening within a pipe, hose or container. Therefore, we offer you several options. One possibility is, to install the Sight Gauge on a Tri-Clamp Flange to get the top view on the flange due to a transparent surface. However, a sidewise insight is also possible with the GMPTEC Sight Gauges.

Sight Gauges

Description

Further benefits and details of the GMPTEC Sight Gauges

The smallest offered Sight Gauges of our portfolio has the shape of a Tri-Clamp closure cap, but it includes glass in the middle and it’s not pure stainless steel. This enables to look inside the container or the tubing.

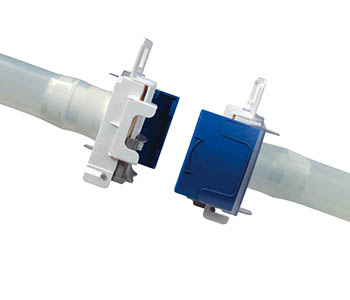

The larger model is a side Sight Gauge. They are like a long tube and end on both sides with Tri-Clamp connections. The Tri-Clamp Flanges are made of sturdy and wear-resistant materials and the area in between is fully of halfway transparent.

Furthermore, the maximum length of these components is 120’’ (equals approximately 305 cm). The maximum allowed working pressure is 12.1 bar and the working temperature reaches from -7° C up to 120°C for the fully transparent polysulfone side Sight Gauges.

A model for higher resistances is the side Sight Gauge made of stainless-steel and glass, which have a working temperature of -30°C to 148°C and a working pressure of 17.8 bar.

Examples of processes and applications of Sight Gauges

- At Pressure Gauges

- Not only chemical processes, but also industrial processes and biopharmaceutical processes

- For visual checking

- Food production

- Cosmetic production

- Purification

- Also filtration processes

- Media preparation

- Formulation

GMPTEC Sight Gauges are conform to:

- USP Class VI

- ISO 10993

- FDA 21 CFR 177.1655

- 3-A Standard

- 12,1 Bar working pressure (polysulfone)

- -7°C to 120°C working temperature (polysulfone)

- 17,5 Bar working pressure (stainless-steel and glass)

- -30°C to 148°C working temperature (stainless-steel and glass)

Available sizes of the Polysulfone Sight Gauges

Standard lengths:

3“ , 6“ , 12“ , 24“ , 36“ , 48“ , 60“ , 120“

| Part number | ID | Flange-OD | Tri-Clamp Size |

|---|---|---|---|

| GMPS075-(3,6,12,24,36,48,60,120) | 0.480″ | 0.992″ | MINI |

| GMPS100L-(3,6,12,24,36,48,60,120) | 0.856″ | 1.984″ | 1″ |

| GMPPS150-(3,6,12,24,36,48,60,120) | 1.356″ | 1.984″ | 1.5″ |

| GMPPS200-(3,6,12,24,36,48,60,120) | 1.856″ | 2.516″ | 2″ |

| GMPPS250-(3,6,12,24,36,48,60,120) | 2.356″ | 3.047″ | 2.5″ |

| GMPPS300-(3,6,12,24,36,48,60,120) | 2.856″ | 3.579″ | 3″ |

The inner diameter within this table are generated by flange diameter

Available sizes of the Stainless-Steel/Glass Sight Gauges

| Part number | ID | OD | Wall | Max. Work pressure(@70˚F) |

|---|---|---|---|---|

| GMP12HP | 0.75 | 1.00 | 0.12 | 150 psi |

| GMP16HP | 1.00 | 1.25 | 0.12 | 250 psi |

| GMP24HP | 1.50 | 1.75 | 0.12 | 200 psi |

| GMP32HP | 2.00 | 2.25 | 0.12 | 100 psi |

| GMP40HP | 2.50 | 2.75 | 0.13 | 100 psi |

| GMP48HP | 3.00 | 3.25 | 0.13 | 100 psi |

| GMP64HP | 4.00 | 4.25 | 0.13 | 100 psi |