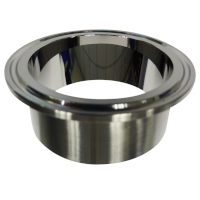

Sanitary fittings made of stainless-steel are the base for many pharmaceutical and biotechnological processes, systems and vessels. By using Tri-Clamps, aseptic connections can be made very quickly and easily, which assures a safe process and the high quality of the final product.

GMPTEC offers a huge selection of different types and materials. Feel free to send us your questions and inquiries!