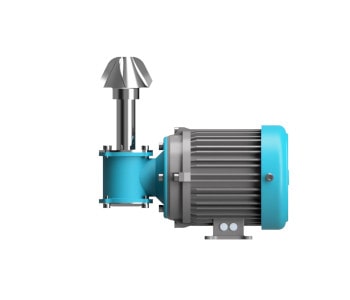

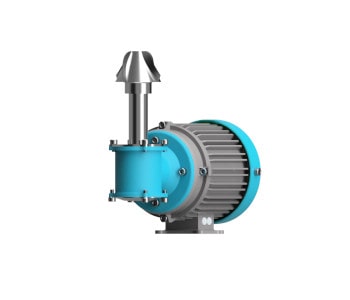

Magnetic Mixer are suitable for the mixing of liquids. The regular range of volume is from 1 to 30.000 liter. Our Magnetic Mixers are available in different scalable sizes, in order to match the numerous volumes. Our Offering also includes special solutions like high-shear mixer, reactor mixer, plastic mixer and special designs of impellers.

Magnetic Mixer

Description

Magnetic Mixer in GMP processes

GMPTEC Magnetic Mixer are a cleaner and more reliable alternative to directly coupled impeller mixers, which usually are installed on top of the vessel. Such mixer types require radial shaft sealings which wear out over time and particles might fall into the mixed product. Moreover, the shaft within the vessel is an obstacle in regards to cleaning as it creates a spraying shadow. Conventional mixer require also baffles which are installed at the vessels wall to achieve an eddying flow pattern. They achieve mixing of the product in the bottom area, the middle and the top, but make the container itself more complicated than necessary and with it also the design of an efficient cleaning system (CIP/SIP).

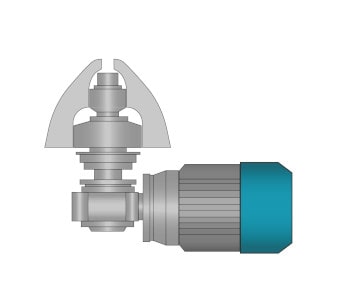

The mixing principle of our Magnetic Mixer is connected to the installing position. The mixer will be placed a little bit offset of the lowest point in the vessel, within the bottom area. From this low position a stirring movement gets started and achieves a natural circulation and mixing in the container without requiring baffles. A suction appears in the lowest center point and generates an upward extrusion at the outer wall of the vessel. This mixing system has many advantages!

Further advantages of the Magnetic Mixer

- Mixing by efficient flow

- Low cost of energy due to smaller actuators

- Reduced shearing effect due to smaller impellers and a smaller rotational speed

- Mixing even at smallest volume

- No radial shaft sealings, since the transmission of power works by magnetic coupling

- More efficient cleaning (CIP/SIP) due to the non-required baffles

- Abrasion resistant bearings instead of a ball bearing

- Dry running properties

- Different materials and impeller design available

- Not only autoclavable, but also CIP/SIP capable

On request we offer the possibility to make CFD analysis, which can be made by an example of chosen vessel shape and mixer design, related to the medium and also it’s temperature. This is the depiction of the mixing procedure and predicted insights about the time and efficiency of the individual mixing process.

Also, on request, we create special shapes for fermenter applications, remaining mixing volume apps or further special tasks.

Whether low or highly viscous liquids can be mixed by the Magnetic Mixer depends on multiple factors, for instance not only on the temperature, but also the volume, the shape of the vessel and consistency. After determining your parameters, we can advise you on which is the best suitable magnetic mixer for your purpose.

Further Vessel Components you can also find here!

Mixer Applications

- Formulation

- Cell culture

- Fermentation

- Preparation

- Filling

- Storage container

- Mobile container

- Suspension container

- Not only high-end food, but also clean cosmetical and chemical processes

Technical Information about the Magnetic Mixer

- 1 Liter – 30.000 Liter volume

- minus 1 – 10 Bar pressure

- 0°C to 150°C working temperature

- materials are synthetics or steel (1.4404 – 316L, 1.4435)

- storage materials are silicon carbide, tungsten carbide, PEEK or diamond coating

- sealing materials are EPDM, Silicone, Viton, PTFE or Kalrez

- surface quality on all product touching areas is SF1

The mixer or it`s components are conform to:

- USP Class VI

- FDA

- 3.1

- IP 55 or higher classed (Actuator)