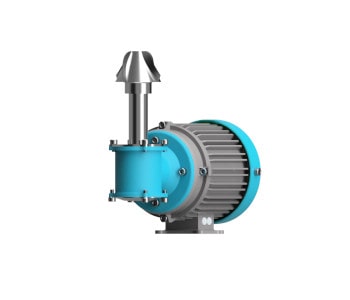

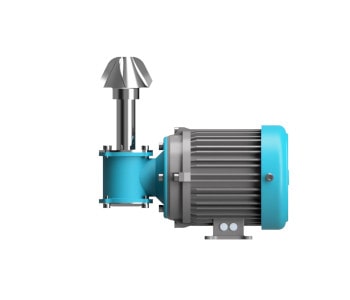

GMP Connect flanges are solid material flanges made of stainless steel. They are mainly used in the vessel construction. But also in production systems with critical dead leg areas the GMP Connect is the preferred solution instead of simple Tri-Clamp connections. The special advantage of this stainless steel component is their construction form, which prevents dead spots in systems and vessels.

GMP Connect

Description

GMP Connect Construction and Advantages

Block flange connections by GMPTEC have a Tri-Clamp outline as their connecting area, just like regular Tri-Clamp fittings. A connection for a transfer of liquid can be established between the two flange contours by installing a gasket in-between them and tightening the connection afterwards. Unlike a regular fitting, the GMP Connect is made of solid material. It becomes conical on the back side, which is the side towards the vessel or pipe.

The opening angle of the funnel-shaped backside enables the product or cleaning agent to reach the gasket area easily. This is not possible with a simple weld-on connection fitting. In those fittings, the product and also cleaning agent would not fill out the entire dead spot inside the short straight pipe in front of the Tri-Clamp or rather the medium will stick nearly statically within this dead spot. The sanitary flanges for GMP Connect will be mounted with two holding cups. Which will be screwed to the flange with stud bolts and rounded nuts.

GMP Connect Types

Weld-On Flange – A block flange to weld onto the vessel, which is available in different sizes and also heights. The different flange heights are important for the installation process. If the flange is to be installed on the vessel within a small radius, then a lot of material of the GMP Connect has to be removed from one side, in order to weld it on flush.

In-Line Flange – A block flange with two Tri-Clamp connections at both sides, for inserting into the piping. Whether sampling valve or blind cover, the third connection on the T-shaped GMP connection valve is positioned directly and also without dead spot at the flow pipe. A fourth connection or similar constructions are also available.

GMP Connects are compliant to:

- PED 97/23 guideline for pressure devices

- CE compliant

- CIP / SIP capable

- Material 1.4401, 14435

- 3.1B material certificate

- Surface RA < 0,6 µm (elements in contact with the product)

- ASTM A270

- SMS 3008

- ISO 1127

- Pressure stages from -1 to 7 bar

- Working temperature from -80°C to 200°C

- Batch ID is marked

Types available:

- Angle-Inline = 1 Inline connection + 1 main connection

- Inline = 2 Inline connection, both sides + 1 main connection

- Inline = 2 Inline connection, both sides + 2 main connections, both sides

- Weld-On-Flange = 1 main connection

Dimensions available:

- Main connection: TC ½“ – 10“, DN8 – DN100, SMS 12 – 102

- In-line connection: weld-on connection piece, Tri-Clamp

- Flange height: 25 mm, 38 mm, 51 mm (more on request)