The CYLINDRAFlow™ valve is manufactured by Nordson MEDICAL and provides an innovative solution for manual flow control within tubing assembles. Each port of the CYLINDRAFlow™ can be connected with flexible tubing, which allows the valve to function as a manifold and replaces multiple plastic fittings. The special design allows to individually control each port and open or block it, in order to control the flow.

CYLINDRAFlow™

Description

CYLINDRAFlow™ – Design and Function

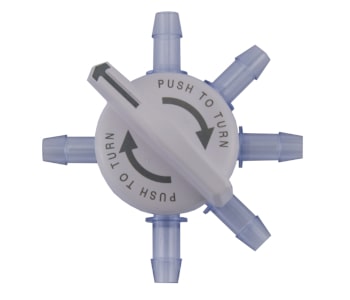

The CYLINDRAFlow housing is made of polycarbonate and has a total of six individual 3/8” hose barbs. These ports are positioned in a circle at the sidewall of the housing. The special design and the internal fluid path with wide radius allow a flow dynamic with very low turbulences, which makes it possible to transport sensitive media, e.g. cell cultures, at higher flow rates.

The white, centered rotary knob is used to actuate the CYLINDRAFlow. A safety mechanism assures that the valve isn’t actuated accidentally during the process. To change the fluid path, the rotary knob needs to be pushed into the housing first. Afterwards, the knob can be turned within a radius of 225° and allows to open the individual ports.

Ports and Settings

Inlet: The valve inlet is positioned a little lower than the other ports, if you look at it from a side-on perspective, which allows easy identification. Additionally, this port cannot be toggled and is always opened. The inlet is used to connect a tubing from your process product line with the valve. Similar to all CYLINDAFlow hose barbs, the tubing connection can be secured by using cable ties or Oetiker clamps.

Stop-Position: If the arrow on the rotary knob is positioned at 45° from the inlet, the valve is locked and doesn’t allow any flow.

Outlet: Positioned in additional 45° steps, there are a total of five controllable outlets. Each outlet can be opened by turning the rotary knob till the arrows points exactly onto the port and locks into position. Until the rotary knob has been positioned and locked in, the fluid path of the CYLINDRAFlow remains closed.

CYLINDRAFlow – Overview

- Ports: 1 x inlet, 5 x outlet

- Settings: 1 x closed, 5 x opened (individually controllable)

- Actuation: rotary knob, manually (Push-to-Turn)

- No pressure drops

- Reduced risk of leakage

- Compact design

- Process simplification (fewer tubing clamps)

- Easy to operate

The following video shows the function and handling of the CYLINDRAFlow:

CYLANDRAFlow™ is compliant to:

- USP Class VI & ISO 10993 Standards

- Gamma Resistant

- Cleanroom Manufactured

- Working Pressure: 1 bar

- QR-Code for Traceability

- Polycarbonate Housing

- Silicone Gasket

- Stainless Steel Spring