If the materials (PP or PVDF) are in contact with the product, we assure that FDA compliant materials are being used and that the systems are cleaned or produced in a cleanroom. If the element is only a non-critical mount or something similar without corresponding requirements, then the products could be not FDA compliant for financial and logistics reasons. We always allow our customers to choose and decide which materials and conformities they require!

GMP Handling and Support

GMPTEC has a broad range of plastic, aluminum and stainless steel production capabilities, which complement our portfolio. They allow us to offer tools and aids that are not directly in contact with the actual product, but facilitate the work and handling within the cleanroom or lab. Mounts, cassettes and shelves are only a few examples.

Our GMP handling and support product range also includes hardware which is needed in the production with disposables, like weldable TPE tubing. Welder and sealer are the key products and allow to sterile weld and seal TPE tubing. All mentioned products can be found here:

Tube Welder and Tube Sealer

Sealer and welder by the manufacturer Vante are officially recommended and sold as the prefer equipment for the C-Flex™ TPE tubing made by Saint-Gobain. Those well-established and further developed devices are available at GMPTEC, including a consulting service and on-site demonstration. We are looking forward to your inquiries!

Individual Designs

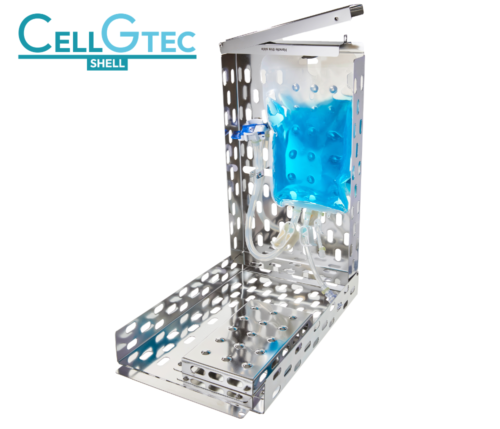

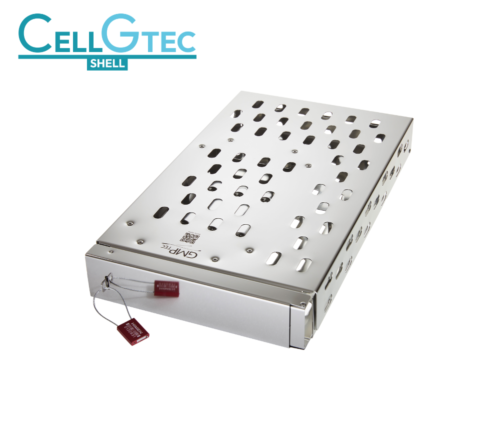

Within GMP productions, laboratories and testing areas, many different multi-use and single-use elements are being used. These elements are often well thought-through and utilized nearly ideal, but it still happens frequently that cables, bags, bottles or tubing are laying around and blocking working space or make it impossible to properly use equipment. There is a huge need for GMP tools and aids elements in many departments, in order to facilitate daily tasks! Our technicians will gladly discuss and develop individual constructions with you – completely free of charge! We can either visit you on-site, or discuss possible solutions via telephone or e-mail. We construct welded, bolted or bent solutions made of plastic, stainless steel or aluminum. These could be mounts for filters or cabinets for tubing, bags and assemblies. Further possibilities are cassettes, storage boxes and racks to store, transport or freeze disposables according to your requirements.

Range and Types of Application:

- Storage

- Assembly-mount

- Transport equipment

- Freezing applications intermediate

- Freezing wagons for active ingredients containers

- Mounts during cell freezing

- Piston holder

- Plastic piping

- Plastic shelves and racks

- Plastic workstations and more

- Welding and sealing

- Sterile connections

Frequently asked questions about GMP Handling and Support:

It would be ideal to discuss the required construction on-site. There you can describe your requirements, the dimensions and the process. Though, in order to get started, a rough sketch would be ideal!

The operating costs are very low if the sterile connection is done by welding. The device requires little compressed air and electricity for a time of about five minutes. However, the acquisition costs of the hardware are to be kept in mind. Also the blades used during the process are single-use only. But welding is still less expensive than regular sterile couplers. Please feel free to contact us in order to get an offer for both options.